Description

Poly-bagging has been recognised as a powerful tool for marketers and used frequently in Australia for many over a decade.

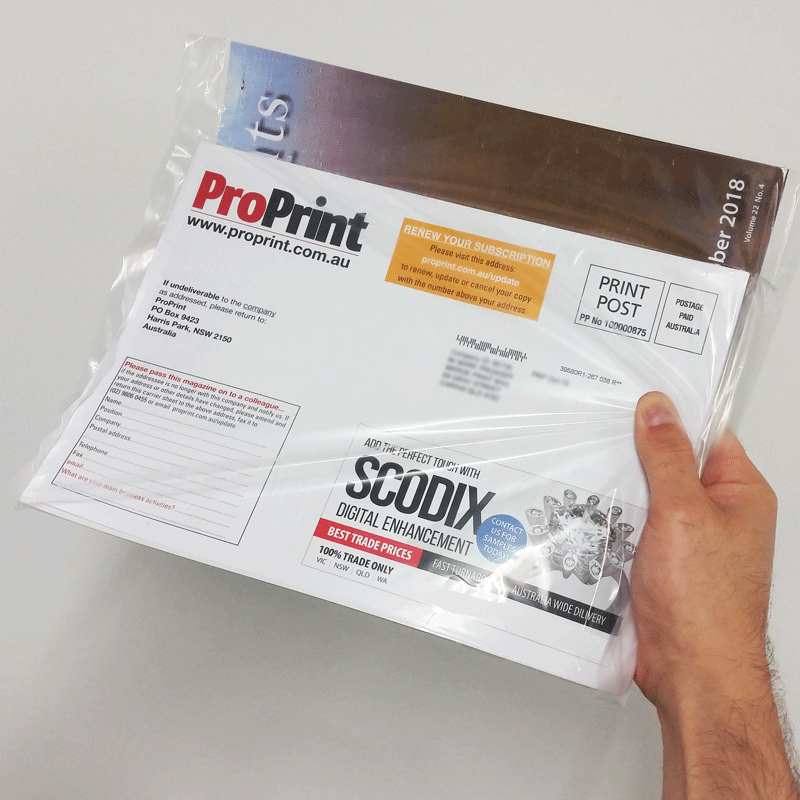

We’ve seen a shift from traditional poly-bagging to poly-bagging that is being used in the direct mail industry as a marketing tool. Imagine receiving a direct mail piece with a clear envelope. Would that peak your interest to see the contents without opening?

The traditional definition is a clear plastic or polyethylene bag used to package several items together, but especially one used to package small supplementary publications from a newspaper or magazine. We’ve also seen entire magazines poly bagged with accompanying pieces like subscription offers and brochures.

High open rates

Experience shows that poly-bagged pieces gets opened more frequently and quicker than traditional direct mail pieces. The visibility of the contents not only stimulates interest but makes more of an impact and lasting impression on the recipient.

Cost efficiency

Poly-bagging keeps your package light and protected from the elements. The ability to poly-bag large pieces could save take rather than having to use large C4 envelopes which can be quite expensive.

Versatility

Poly-bagging is probably the most versatile housing for your mail piece. Poly-bagging conforms to the size of your package, rather than the package having to conform to the size of your envelope. The poly can take the shape of any size mail piece, from a small and thin package to a reasonably large and thick package. The poly also makes your piece durable and well protected from water damage and some ripping. Lastly, polybagging machines can produce as high as 10,000 pieces per hour. Poly-bagging is time effective and efficient, keeping your important turnaround times to a minimum.

Benefits

- 100% environmentally-friendly biodegradable poly

- As many pieces as required in a package

- Fast turnaround times due to high speed poly-bagging capabilities

- We can insert inside the publication (blow in insert)